OUR PRODUCTS

Precision Crafted Pins, Punches, Perforators & Specialized Components for Dies and Molds

Royal Pins is known for our innovative, high-caliber products. Whether you need standard pins, punches, perforators, or a custom project, Royal Pins is your trusted partner.

MATERIALS

COATINGS

- Ion Nitriding

- Titanium Nitride

- Black Oxide

- Tungsten DiSulfide (WS2)

STYLES

Decimal (incl. Fractionals)

- Perforators / Core Pin Blanks

- Quill Punches / Core Pin Blanks

- Punch Blanks

- Bevel Headed Punches

- Die Kicker Pins

- Slug Ejector Pins & Components

- TRUE-HARD Ejector Pins

- HARD-CORE Ejector Pins

- KNIGHTRIDE Hotwork Ejector Pins

- Standard Hotwork Core Pins

- KNIGHTRIDE Ejector Sleeves

- Interlocks

- Custom punches & pins

Metric

- Metric Perforators / Core Pin Blanks

- Metric Punch Blanks

- Metric TRUE-HARD Ejector Pins

- Metric KNIGHTRIDE Hotwork Ejector Pins

CUSTOM MODIFICATIONS

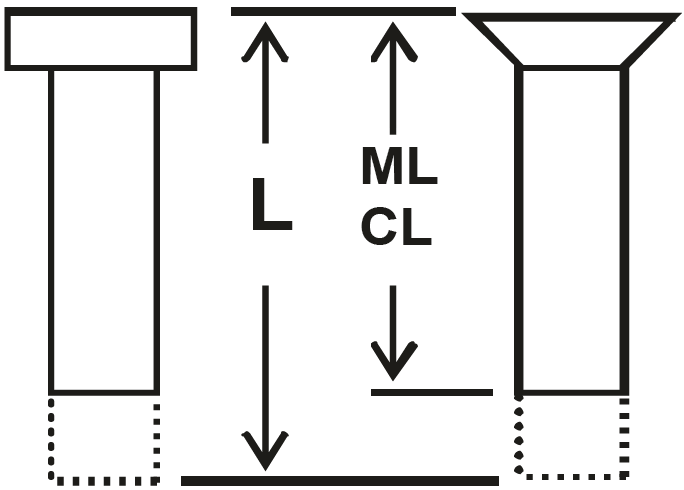

REDUCED BODY LENGTH

Stock removal from the front-end. Tolerance of +.015″/-.000″ [+0.5/-0.0 mm] or +/-.001″ [+/-0.03 mm]

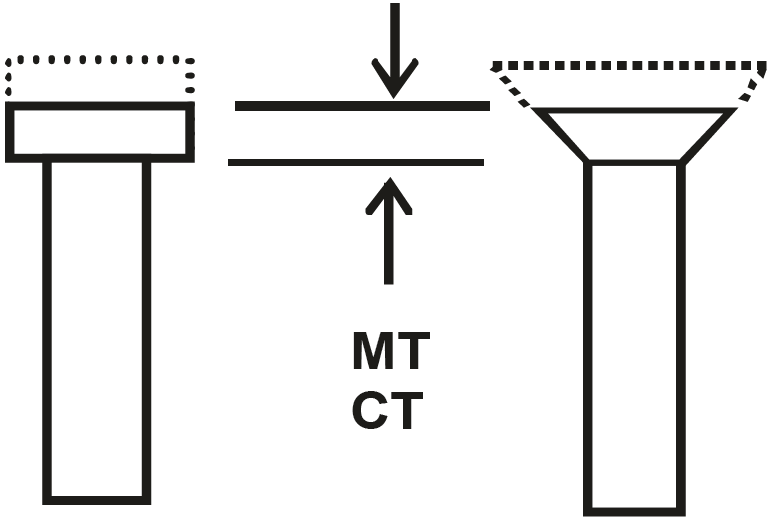

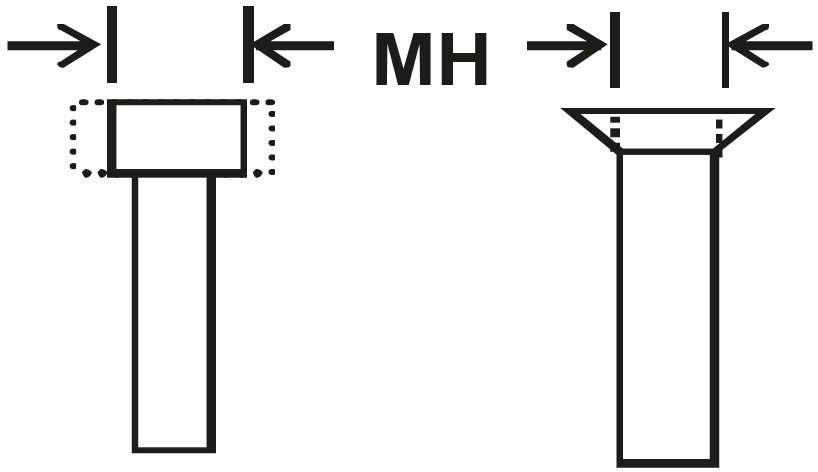

REDUCED HEAD THICKNESS

Stock removal from the back-end (shortens overall length). Tolerance of +.010″/-.000″ [+0.3/-0.0 mm] or +/-.001″ [+/-0.03 mm]

Royal's TRUE-HARD Pins

Made from superior quality, wear-resistant M-2 high speed steel, our trademark TRUE-HARD pins are through-hardened and double-tempered to 60-63 RC in our specially developed, computer-regulated vacuum heat treatment equipment for maximum toughness and durability before being precision-ground to ensure high accuracy and finish.

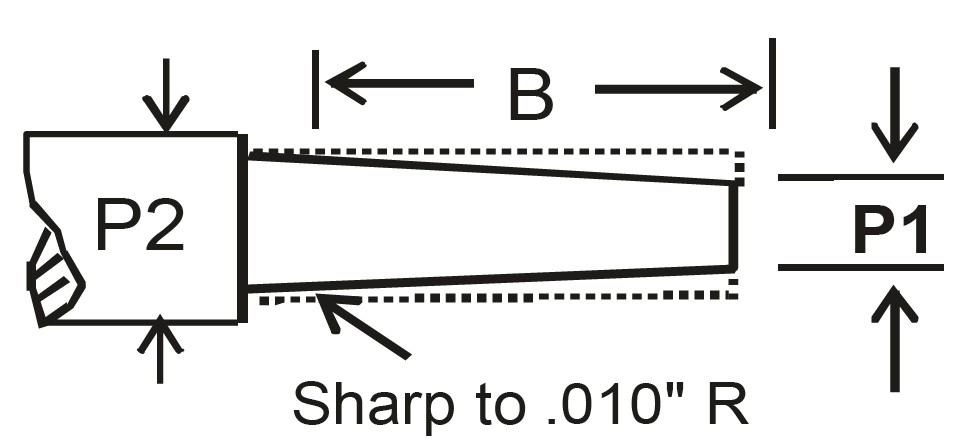

CORE PIN STEP – STRAIGHT

Max affected length = .750″. Can be combined with reduced body length or head thickness. Tolerance of +/-.001″

CORE PIN STEP – DRAFT

Max affected length = .750″. Can be combined with reduced body length or head thickness. Tolerance of +/-.001″

Royal's HARD-CORE Series

Built to be the most durable pins around, our trademark HARD-CORE pins offer a through-hardened core of 50-55 RC and an ion-nitrided casing of 65-74 RC through a proprietary process that prevents surface nicking and flaking that can afflict other nitrided pins, assuring a long life and enduring performance for even the toughest of jobs

REDUCED HEAD DIAMETER

Cannot be smaller than radius of body. Tolerance of +.000″/-.010″ [+0.0/-0.3 mm] or +/-.001″ [+/-0.03 mm]

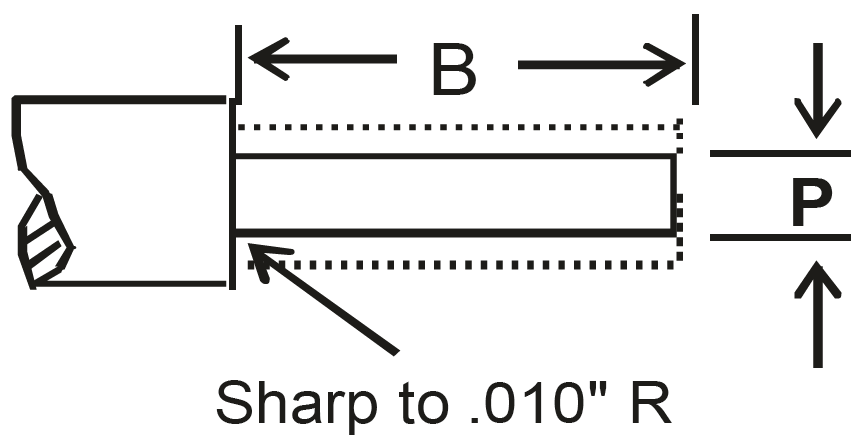

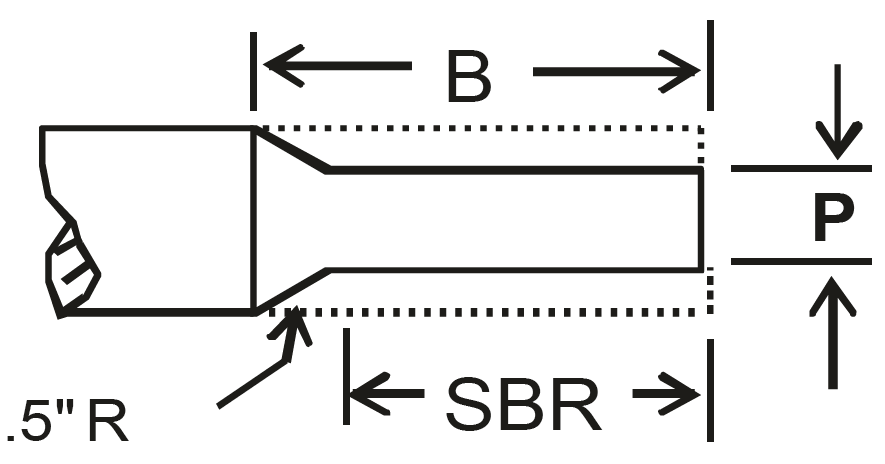

PUNCH STEP

Use B for no shoulder, otherwise use SBR. Max affected length = .750″. Tolerance of +.06″/-.00″

Royal's KNIGHTRIDE Series

Precision-crafted from the finest grade of H-13 hotwork die steel, our trademark KNIGHTRIDE pins are hot-forged and stress-relieved for uniform grain flow and high tensile strength before being through-hardened to 41-45 RC with an ion-nitrided surface of 65-74 RC and a diffusion layer between the case and the core for the perfect balance of tough and flexible

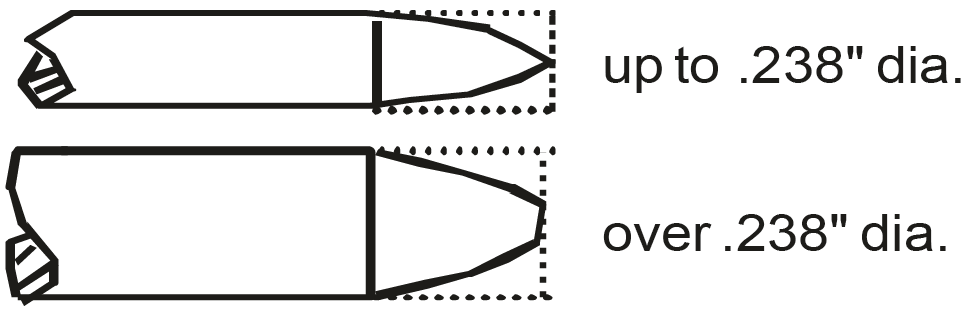

PILOT NOSE

Included in overall length. Radius = .119″. Tolerance is the same as the selected pin

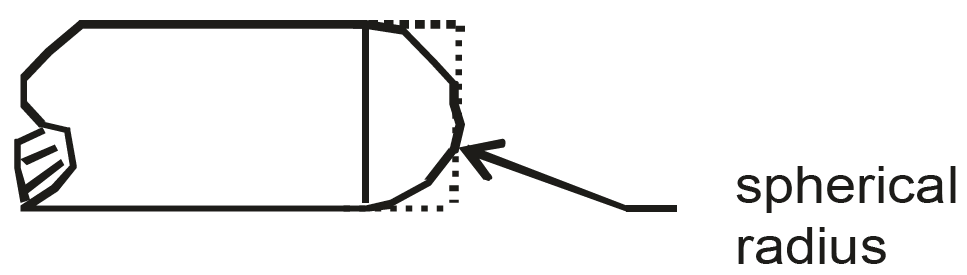

SPHERICAL RADIUS

Radius = 1/2 diameter. Can be combined with reduced body length or head thickness. Tolerance is the same as the selected pin

PRODUCT BY MATERIAL

M-2 High Speed Steel

Decimal (incl. Fractionals)

- Perforators / Core Pin Blanks (RQA, RQB, B & AB)

- Bevel Headed Punches (BH)

- Punch Blanks (CPB, PPB & EB)

- TRUE-HARD Ejector Pins (PT & PTD)

- Custom punches & pins

Metric

- Metric Perforators / Core Pin Blanks (MQA & MQB)

- Metric Punch Blanks (MPB)

- Metric TRUE-HARD Ejector Pins (MPT)

O-1 Oil Hardening Tool Steel

Decimal (incl. Fractionals)

- Quill Punches / Core Pin Blanks (SQ)

- Bevel Headed Punches (BH)

- Die Kicker Pins (EP)

- Slug Ejector Pins & Components (EJ & CS)

- Interlocks (TIF – TIM)

- Custom punches & pins

H-13 Hotwork Die Steel

Decimal (incl. Fractionals)

- HARD-CORE Ejector Pins (RHX)

- KNIGHTRIDE Hotwork Ejector Pins (RX)

- Standard Hotwork Core Pins (RC & RCX)

- KNIGHTRIDE Ejector Sleeves (RSL)

- Custom punches & pins

Metric

- Metric KNIGHTRIDE Hotwork Ejector Pins (ME)

Royal Diversified Products, Inc.

287 Market Street, P.O. Box 444

Warren, RI 02885-0444 USA

Phone/Receptionist: 401-245-6900

Order Desk: 800-556-7916

Fax: 401-247-2231